Table of contents

Chapter 1: What is a cement bulker?

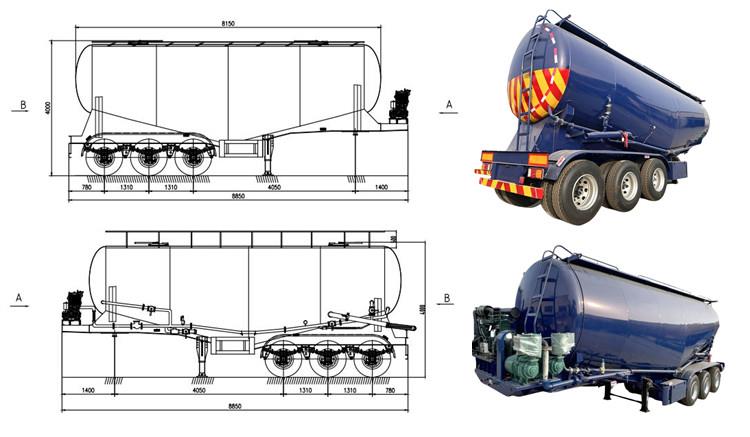

1.1 Cement bulker dimension

1.2 Cement bulker price in indonesia

Chapter 2: What is the capacity of a cement tanker?

Chapter 3: What does a cement bulker do?

A cement bulker is a type of specialized trailer used for transporting bulk quantities of cement. It is designed to safely and efficiently transport dry bulk cement from manufacturing plants to construction sites or storage facilities.

The bulker has a large, sealed tank with multiple compartments to hold and separate the cement. The cement bulker is usually made of high-strength steel or aluminum to withstand the weight of the cargo and ensure structural integrity during transportation. It is often equipped with a pneumatic system that uses compressed air to discharge the cement through a hose or pipe.

Overall, cement bulker provide an efficient and convenient means of transporting large quantities of cement in bulk. The cement bulker plays a crucial role in the logistics and supply chain of the construction industry.

Model: Most popular 3 axle 35cbm cement bulker

Dimension: 8850*2500 *4000mm

Tanker body material: high strength wear-resistance steel

Payload: 35cbm

Axles: 3 axles

Tire: 12 units

Tank body thickness: 3.5mm

Compressor: BOHAI 12m3 double cylinder air compressor

Diesel Engine: WEICHAI Brand

Suspension: Heavy duty mechanical suspension

Landing gear: JOST

Brake system: WABCO

The cost of a cement bulker can vary based on several factors such as the size, brand, features, and market conditions. The price range for a new cement bulker typically starts from around $14,000 to over $20,000.

It's important to note that prices may have changed since then due to various factors like inflation, changes in manufacturing costs, and market dynamics. To get the most accurate and up-to-date information on the current cost of a cement bulker, it would be best to consult manufacturers, dealers, or industry publications specialized in commercial vehicles and tankers.

The approximate prices of some commonly sold sizes are listed below, please leave a message to inquire about the quote!

2 axle 25cbm cement bulker price: 14300 USD

3 axle 35cbm cement bulker price: 16200 USD

3 axle 43cbm cement bulker price: 16700 USD

3 axle W type 50 cbm cement bulker price: 18400 USD

The capacity of a cement bulker can vary depending on its design and specifications. Typically, cement bulkers are used to transport bulk quantities of cement from production plants to construction sites or storage facilities. The capacity of cement bulker is measured in terms of volume, usually in cubic meters (m³) or in metric tons (tonnes).

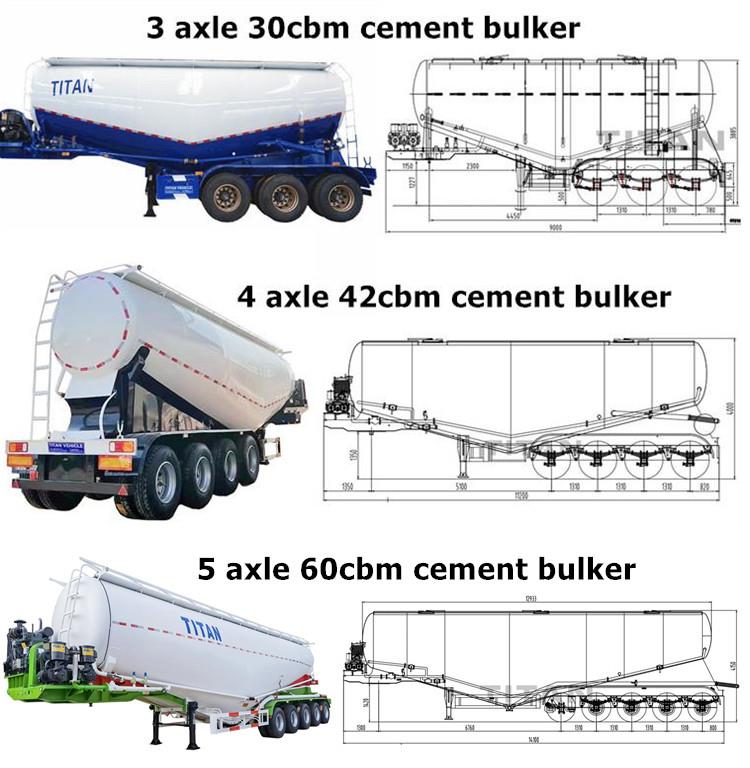

Commonly, cement bulkers have capacities ranging from 25 to 60 cubic meters or approximately 30 to 70 metric tons. However, it's important to note that these values can differ based on the specific model, configuration, and regional regulations.

To determine the exact capacity of a particular cement bulker, it's best to refer to the manufacturer's specifications or consult with the supplier or dealer who can provide accurate information based on the specific make and model.

We can customize cement bulker according to your requirements. Available in V-types and W-shaped, and the materials are carbon steel, stainless steel, and aluminum alloy. Below I will list several common sizes.

2 axle 25cbm bulk cement bulker capacity: 30 ton

3 axle 42cbm cement bulker capacity: 50 ton

3 axle 50cbm cement bulker capacity: 60 ton

4 axle 60cbm cement bulker capacity: 70 ton

Here are some common applications of cement bulker:

Construction Industry: Cement bulker is extensively used in the construction industry to transport bulk quantities of cement from production facilities or ports to construction sites. Cement is a primary component in concrete production, and these trailers ensure the efficient and timely delivery of cement to support construction projects.

Infrastructure Development: In large-scale infrastructure development projects like roads, highways, bridges, and airports, cement bulker play a crucial role. They transport cement to the project sites, where it is used for various purposes such as concrete production, soil stabilization, and grouting.

Cement Plants and Distribution Centers: Cement bulker trailers are utilized for transporting cement from manufacturing plants to distribution centers or directly to retailers. These trailers enable the safe and reliable delivery of cement to different locations, allowing the smooth functioning of the supply chain in the cement industry.

Emergency and Disaster Relief: In the aftermath of natural disasters or emergencies, cement bulker can be utilized for delivering cement to affected areas. Cement plays a vital role in temporary shelter construction, reconstruction efforts, and infrastructure repair, and these trailers enable the efficient transportation of cement to support relief operations.

Cement bulker in factory production

Here's how a cement bulker typically operates:

1. Loading: The bulker is positioned near the cement loading area at the manufacturing plant. The cement is mechanically loaded into the sealed compartments of the bulker, ensuring that it remains dry and uncontaminated.

2. Transportation: Once loaded, the cement bulker travels on roads to the designated destination. It may be a construction site, a storage unit, or a distribution center.

3. Unloading: At the destination, the bulker is positioned in a suitable location. A pneumatic system, often powered by compressed air, is used to discharge the cement from the compartments. The process occurs through a hose or pipe connected to the bulker. The cement flows out under pressure and is directed to the desired location, such as a silo or mixing area.

4. Safety and Efficiency: Cement bulkers are designed with safety features to prevent contamination, spilling, or leakage of the cement during transportation. They also aim to maximize efficiency, enabling the smooth flow of cement and minimizing delivery times.