Chapter 1: What is bulk cement trailer?

1.1 What material is cement tanker trailer?

1.2 What is the capacity of cement tanker trailer?

1.3 How much does a dry bulk trailer cost?

1.4 Advantages of cement tanker trailer in Jamaica

Chapter 2: What is the use of cement tanker trailer?

Chapter 3: How does a bulk cement tanker work?

A bulk cement trailer is a specially designed vehicle used for transporting large quantities of cement from the manufacturing plant to construction sites or storage facilities. It is commonly used in the construction industry to ensure a continuous supply of cement for various projects.

A bulk cement trailer is typically a heavy-duty truck or semi-trailer with a large cylindrical tank on its back. The tank is specifically designed to carry a significant volume of loose cement powder. The trailer is usually made of durable materials like steel to withstand the weight and pressure of the cement load.

The bulk cement trailer in Jamaica is equipped with a powerful air compressor system, which is used to blow compressed air into the tank to fluidize the cement. This process helps in ensuring easy discharge or unloading of the cement at the destination. The bulk cement tanker trailer for sale may also have specialized compartments or compartments with individual compartments to transport different types of cement or additives separately.

The bulk cement trailer plays a crucial role in maintaining the efficiency of the construction process by providing a convenient and secure means of transporting cement in large quantities. It eliminates the need for manual handling of cement bags, reduces labor, and helps in speeding up the construction projects.

Moreover, the bulk cement trailer for sale helps in preventing cement contamination and spoilage by protecting the cement from exposure to moisture and impurities during transportation. This ensures the quality and integrity of the cement, resulting in better construction outcomes.

In a nutshell, the bulk cement trailer in Jamaica is an essential equipment in the construction industry, enabling the efficient and reliable transportation of cement in bulk quantities, supporting the smooth progress of construction projects.

Cement tanker trailer in Jamaica is typically made of high-quality materials to ensure durability and safety during transportation. The most common material used for cement tanker trailers is carbon steel.

The main body or tank of the cement tanker trailer in Jamaica is usually constructed from carbon steel that is strong and resistant to the pressure and weight of the cement load. High-tensile steel is often preferred for its ability to withstand heavy loads and harsh road conditions.

The tank is constructed with reinforced ribs and welded joints to enhance its structural integrity and prevent leakage during transit. The steel used is often treated with anti-corrosion coatings or paint to protect it from rust and other environmental factors.

Additionally, the tank interior is typically coated with special linings or materials that are resistant to the corrosive nature of cement, preventing damage to the tank and maintaining the quality of the cement being transported.

Other components of the cement tanker trailer, such as the chassis, axles, suspension system, and braking system, are also primarily made of steel or other durable materials to ensure strength, stability, and reliability on the road.

The construction and material selection of the cement tanker trailer are crucial to ensuring safe transportation and preventing accidents or cement contamination.

Overall, the cement tanker trailer in Jamaica is constructed using high-quality steel and other reinforced materials to withstand the demands of transporting large quantities of cement and to maintain the integrity and quality of the cement throughout the journey.

And there is also a wheat flour tanker trailer typically made of food-grade stainless steel. Food-grade stainless steel is preferred for transporting edible products like wheat flour due to its excellent hygiene, durability, and resistance to corrosion. This material ensures that the wheat flour remains uncontaminated and safe for consumption during transportation.

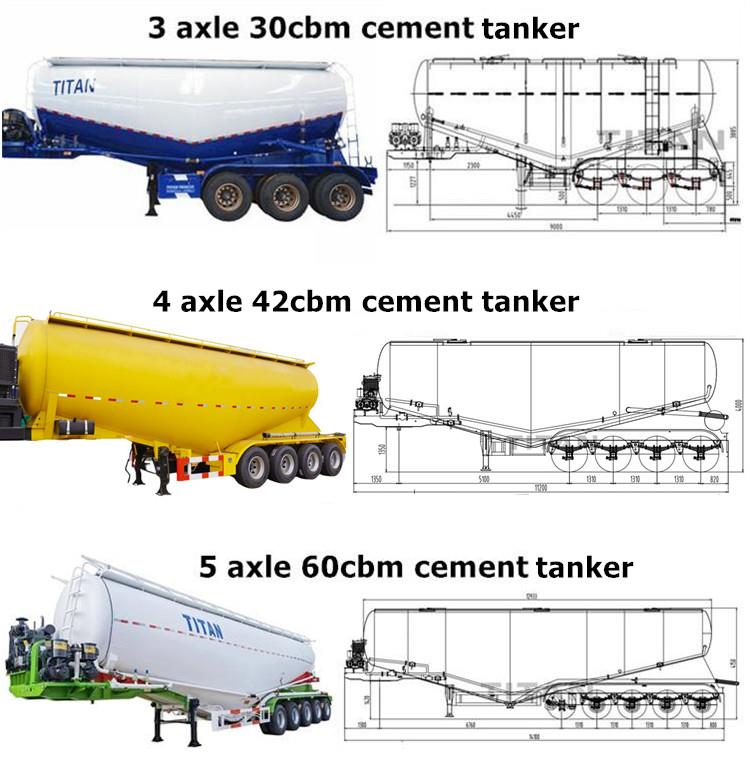

The capacity of a cement tanker trailer in Jamaica can vary depending on its design, configuration, and regulations in different regions. However, common capacities range from 30 to 60 metric tons or even more.

The capacity of a cement tanker trailer for sale is typically measured in cubic meters (m³) and refers to the maximum volume of cement that can be transported in a single load. For example, a 3 axle cement tanker trailer may have a capacity of around 30-50 cubic meters for bulk cement transportation.

Regulatory restrictions and road limitations can also influence the permissible capacity of cement tanker trailers in different countries or regions. Local transportation regulations and infrastructure considerations, such as weight restrictions and axle load limits, play a role in determining the maximum load capacity.

It's essential for truck drivers, logistics personnel, and manufacturers to comply with these regulations and ensure that the cement tanker trailer's capacity adheres to legal requirements for safe and efficient transportation.

Dry Bulk Cement Tanker Trailer for Sale in TITAN Vehicle

The cost of a dry bulk trailer can vary depending on several factors such as the trailer's size, capacity, manufacturer, specifications, and any additional features or customization options. The prices of trailers can also vary across regions and countries due to factors such as local manufacturing costs, import/export expenses, and taxes or tariffs.

It's also important to note that prices can fluctuate over time due to market conditions and inflation. Therefore, it's challenging to provide an exact figure. However, I can give you a general idea of the price range. On average, a dry bulk cement tanker trailer can cost anywhere from $15,000 to $20,000 or more, depending on the factors mentioned above.

Additionally, specialized trailers with unique features or specific requirements might incur higher costs. It's advisable to reach out to trailer manufacturers, dealerships, or distributors to obtain up-to-date and accurate pricing information based on your specific needs and location.

Keep in mind that maintenance costs, spare parts, and operational expenses should also be considered when calculating the overall investment required for a dry bulk trailer. Investing in a high-quality, durable trailer from a reliable manufacturer is important to ensure long-term performance, efficient operations, and subsequent return on investment.

1. Efficient Transportation: Cement tanker trailers are specifically designed to safely transport large quantities of cement or other bulk materials. They have a high carrying capacity, allowing for efficient delivery of cement to construction sites or storage facilities in Jamaica.

2. Product Integrity: Cement tanker trailers are built with materials and mechanisms that ensure the integrity and quality of the cement during transportation. They are sealed and equipped with features like air-tight compartments and discharge systems, preventing contamination or spoilage of the cement.

3. Flexibility and Versatility: Cement tanker trailers are versatile and can accommodate different types of cement, including bulk cement, powdered cement, or fly ash. This flexibility allows for the transportation of various cement products as per the project requirements in Jamaica.

4. Cost Efficiency: By using cement tanker trailer in Jamaica, construction companies or distributors in Jamaica can streamline their logistics and transportation processes, reducing the need for multiple trips or alternative transportation methods. This can result in cost savings in terms of fuel, labor, and time.

5. Accessibility to Remote Areas: Cement tanker trailer for sale in Jamaica can reach remote or challenging construction sites, allowing for the timely delivery of cement even in areas that are difficult to access. This is particularly beneficial in Jamaica, where construction projects might be scattered across diverse geographical terrain.

6. Durability and Safety: Cement tanker trailers are built with sturdy materials and undergo rigorous quality standards, ensuring durability and safety during transportation. They are designed to withstand harsh road conditions, ensuring the protection of the cement cargo and minimizing the risk of accidents or spillage.

7. Environmental Considerations: Cement tanker trailer for sale offer an eco-friendly transportation solution as they help reduce the carbon footprint associated with cement distribution. By efficiently delivering large quantities of cement in a single trip, they contribute to lowering emissions and optimizing resource utilization.

Dry Bulk Cement Tanker Trailer for Sale in Jamaica

The cement tanker trailer for sale in Jamaica is used for transporting bulk cement or powdered materials. It is specifically designed to ensure the safe storage and transportation of cement to construction sites, cement plants, or other locations where the material is needed. The cement tanker trailer typically has a large cylindrical tank with a conical shape at the bottom, allowing for efficient loading and unloading of cement. These trailers are commonly used in the construction and infrastructure industries, where cement is a fundamental component in the production of concrete.

The cement tanker trailer in Jamaica finds application in various industries and scenarios. Here are a few common applications:

1. Construction Industry: Cement tanker trailers play a crucial role in the construction industry. They transport bulk quantities of cement to construction sites. The cement is then used for various purposes, such as concrete production, mortar mixing, and other construction processes.

2. Cement Plants: Cement manufacturing plants often require the transportation of cement to different locations. Tanker trailers provide a safe and efficient means of transporting cement from the production plant to storage facilities or distribution centers.

3. Infrastructure Projects: Large-scale infrastructure projects such as highways, bridges, dams, and buildings also require significant amounts of cement. Cement tanker trailers help in supplying the necessary cement to these project sites, ensuring a continuous and steady supply.

4. Remote or Difficult-to-Reach Areas: In areas with challenging terrain or limited access, cement tanker trailers are advantageous. These trailers can navigate through narrow roads or rough terrains to deliver cement to remote construction sites.

5. Export and Import: Cement tanker trailers are utilized for the export and import of cement. They transport cement internationally or domestically between different regions or countries, supporting the global cement trade.

Overall, cement tanker trailers are crucial for the transportation of cement in bulk quantities, ensuring a reliable supply and supporting various construction and infrastructure projects.

Bulk cement tanker trailer in Jamaica operates with a specific mechanism to transport and discharge cement efficiently. Here's how it generally works:

1. Structure: A bulk cement tanker trailer typically consists of a hollow cylindrical tank made of high-quality steel. The tank is designed to withstand the pressure exerted by the cement load during transportation.

2. Loading: The cement is loaded into the tanker through openings at the top of the tank using pneumatic systems. Compressed air is used to force the cement particles into the tanker, filling it to its capacity.

3. Transportation: Once loaded, the bulk cement tanker trailer is attached to a truck tractor or other suitable hauling vehicle to transport it to the desired destination. The tanker is equipped with axles, suspension systems, and braking mechanisms to ensure safe and stable transportation.

4. Unloading: When it's time to discharge the cement, the tanker employs a pneumatic unloading system. The process involves the following steps:

- The truck tractor stops at the unloading area, and the tanker is positioned appropriately.

- Compressor: A powerful air compressor, typically mounted on the tractor, supplies compressed air to the tanker.

- Discharge Pipes: The compressed air is directed through a network of discharge pipes or hoses connected to the tanker. These pipes are equipped with valves and fittings for control and ease of operation.

- Fluidization: The compressed air creates fluidization within the tanker, loosening the cement particles and causing them to flow like a fluid.

- Gravity Flow: With the cement particles fluidized, gravity takes over, and the cement flows down through the discharge pipes to the desired location, such as a storage silo, a concrete mixer, or directly into the construction site.

It's important to note that different types bulk cement tanker trailers may have variations in the specific equipment and mechanisms used, but the basic principle of pneumatic loading and unloading remains consistent.