Table of contents

Chapter 1: What is the use of cement tanker?

Chapter 2: How much does a cement tanker hold?

Chapter 3: Operation guide of cement tanker

Cement tanker is specifically designed for transporting cement from the production facilities to construction sites. It is a specialized tanker trailer that has a large cylindrical container or tank used to transport bulk quantities of cement. The tank is usually made of steel and is built to withstand the weight and pressure of the cement load.

Cement tankers are equipped with a variety of features to ensure safe transportation and efficient delivery of cement. These features may include pneumatic systems, which use compressed air to discharge the cement at the destination, and a fluidization system to keep the cement powder flowing smoothly during transportation.

The primary purpose of a cement tanker is to transport cement in bulk, eliminating the need for individual bags or smaller containers. This method is more cost-effective and time-efficient, especially for large construction projects where a significant amount of cement is required.

Here are some common applications of cement tankers:

1. Construction Industry: Cement tankers are extensively used in the construction industry to transport bulk quantities of cement for various projects such as roads, bridges, buildings, and dams. They enable the efficient and timely supply of cement to construction sites.

2. Cement Plants: Cement tanker in Uruguay is used to transport cement from manufacturing plants to storage facilities or distribution centers. They ensure a smooth and reliable flow of cement throughout the supply chain.

3. Infrastructure Development: Cement tanker play a crucial role in large-scale infrastructure development projects where massive amounts of cement are required. They help meet the demand for cement in the construction of highways, airports, railways, and other infrastructure projects.

4. Cement Trading: Cement tankers are also utilized in the cement trading industry, where cement is transported from one location to another for sale or distribution. They facilitate the movement of cement between different regions or countries.

Overall, cement tankers are essential vehicles in the cement industry, enabling the efficient transportation and delivery of cement for construction projects of varying scales.

The capacity of cement tanker in Uruguay can vary depending on its design and specifications. Typically, cement tanker is used to transport bulk quantities of cement from production plants to construction sites or storage facilities. The capacity of cement tanker is measured in terms of volume, usually in cubic meters (m³) or in metric tons (tonnes).

Commonly, cement tankers have capacities ranging from 25 to 60 cubic meters or approximately 30 to 70 metric tons. However, it's important to note that these values can differ based on the specific model, configuration, and regional regulations.

To determine the exact capacity of a particular cement tanker, it's best to refer to the manufacturer's specifications or consult with the supplier or dealer who can provide accurate information based on the specific make and model.

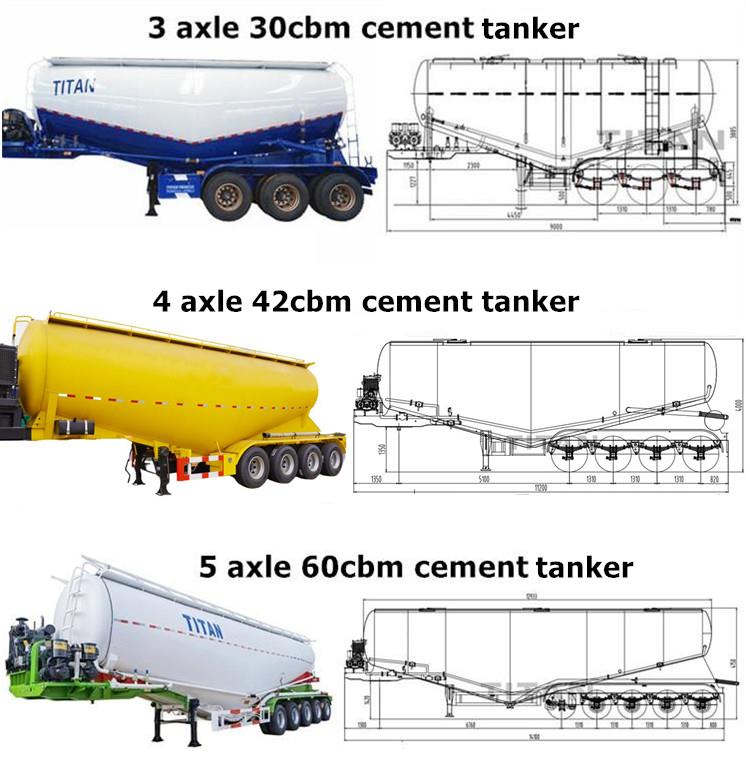

We can customize cement tanker in Uruguay according to your requirements. Available in V-types and W-shaped, and the materials are carbon steel, stainless steel, and aluminum alloy. Below I will list several common sizes.

2 axle 25cbm cement tanker capacity: 30 ton

3 axle 42cbm cement tanker capacity: 50 ton

3 axle 50cbm cement tanker capacity: 60 ton

4 axle 60cbm cement tanker capacity: 70 ton

Preparations before using the cement tanker

1. Check the fastening situation of each connect parts, especially notice the connect parts on Steering, braking, suspension, wheels and kingpin.

2. Check the brake system if is normal and the pipeline if leakage air.

3. Check the pressure of tires if meet the regulation.

4. Check the lighting system (turning light, brake light and taillight) if is working in normal.

How to load bulk cement into pneumatic cement tanker?

1. Drive the cement tanker under the bulk powder silo and open the pressure relief valve.

2. Open the manhole cover after exhausting. Make sure the feed opening align with the manhole, close the other valves and start Loading (Never open the cover under pressure).

3. Load the bulk cement on rated tonnage. Close and lock the manhole cover after cleaning the powder around the manhole.

4. Clean the powder on working platform. Close the Pressure relief valve.

How to unload bulk cement from cement tanker?

1. Connect the discharge pipe to inlet of cement tanker.

2. Check the ball valve, pressure relief valve, external air connector, discharge butterfly valve if is closed.

3. Open the Intake valve of cement tanker, start the engine to drive the PTO and air compressor and filling the air into tank. Adjust the Hand Throttle to make tachometer read on 900r/min.

4. In addition, the cement tanker also can be filled through an external air source.

5. Open the ball valve when the read of discharge pressure meter meets the requirements then open the discharge butterfly valve to unload the bulk cement.

6. When the tanker pressures reduce to the 10% of working pressure, the unloading can be finished. Relax the hand throttle and unbutton the PTO.

7. Close the discharge butterfly valve, open the pressure relief valve.